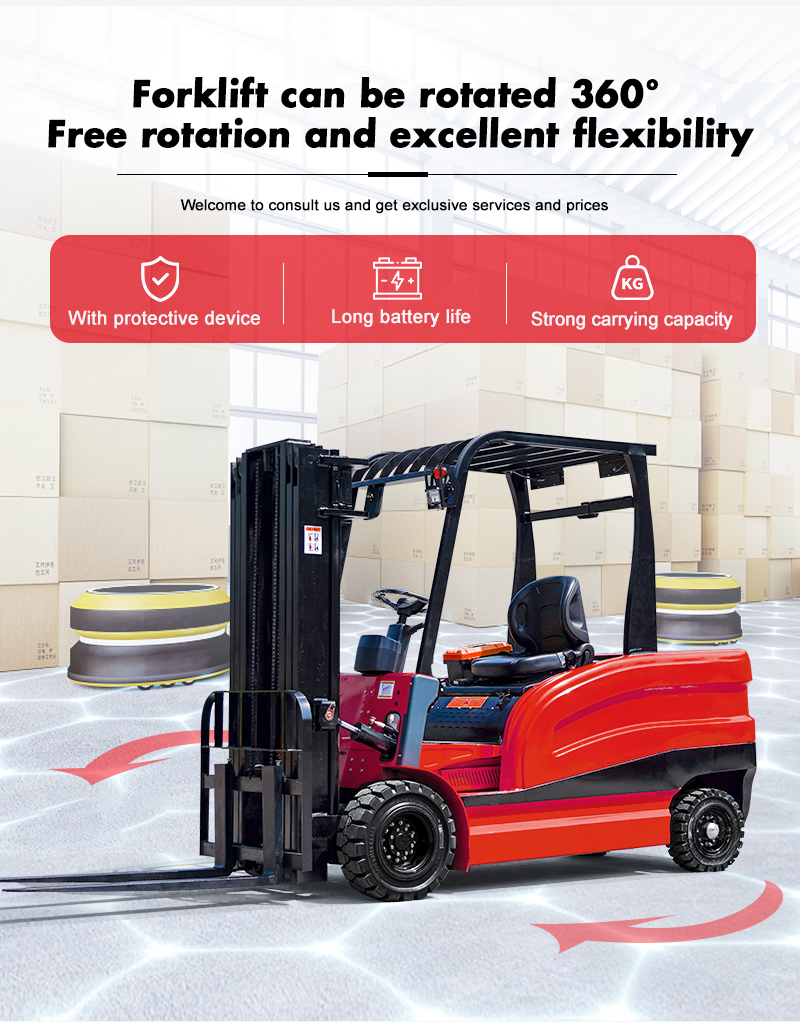

High Performance Electric Forklift: Intelligent Operation, Superior Efficiency

Advanced Control Systems Meet Ergonomic Design for Unmatched Productivity and Operator Comfort

Description

Redefining Electric Forklift Performance

Modern warehouses and distribution centers demand more than just basic material handling equipment – they require intelligent solutions that enhance both operational efficiency and workplace environment. Our High Performance Electric Forklift represents the culmination of years of engineering innovation, specifically designed to meet these dual challenges through advanced control technology and operator-focused design.

Unlike conventional electric forklifts that simply replace power sources without reimagining operational dynamics, this model integrates sophisticated electronic control systems with ergonomic principles to create a truly transformative material handling experience. The result is equipment that doesn't just perform tasks, but enhances your entire operational ecosystem through precision control, reduced operational stress, and adaptive performance characteristics.

Intelligent Control Systems

Precision Electronic Management

At the core of this forklift's performance advantage lies its advanced electronic control system, which manages every aspect of operation with digital precision. Unlike hydraulic or basic electrical systems that operate with inherent variability, our computerized control platform ensures consistent, repeatable performance regardless of load conditions or operator experience level.

The system continuously monitors multiple operational parameters – including load weight, lift height, travel speed, and battery status – automatically adjusting performance characteristics to optimize both efficiency and safety. This intelligent management extends to the power delivery system, where sophisticated algorithms ensure smooth acceleration and deceleration profiles that minimize load shifting and reduce wear on components.

Adaptive Performance Characteristics

What truly sets this control system apart is its ability to adapt to specific operational requirements. Through customizable performance profiles, the forklift can be optimized for different applications: precision mode for delicate cargo handling, efficiency mode for maximum battery conservation, or high-productivity mode for demanding operational tempo.

The system also incorporates learning capabilities that adjust to operator patterns, creating a increasingly intuitive interaction between human and machine. This adaptive intelligence reduces the learning curve for new operators while enhancing performance for experienced users, creating a versatile tool that improves with use.

Advanced Performance Features

Regenerative Power Management

The forklift incorporates an advanced regenerative braking system that captures kinetic energy during deceleration and converts it to electrical energy for battery recharge. This system not only extends operational time between charges but also reduces brake wear significantly. In operations with frequent start-stop cycles, this feature can increase battery runtime by up to 18% while substantially reducing maintenance requirements.

Smart Fleet Integration

For operations utilizing multiple forklifts, our model offers sophisticated fleet integration capabilities. The onboard telematics system provides real-time performance data, maintenance requirements, and utilization metrics that can be integrated with your warehouse management system. This connectivity enables optimized fleet deployment, preventive maintenance scheduling, and comprehensive operational analytics.

Environmental Adaptability

The forklift maintains consistent performance across varying environmental conditions. The sealed electronic components resist moisture and dust infiltration, while the temperature management system ensures optimal battery and electronic performance in both heated warehouses and cold storage applications. Specialized packages are available for extreme conditions, including freezer applications and corrosive environments.

Technical Specifications

|

Wheelbase(mm) |

1930 |

Minimum turning radius(mm) |

2670 |

|

Front overhang(mm) |

300 |

Load center distance(mm) |

500 |

|

Front wheel width(mm) |

1010 |

Front wheel specifications(/) |

28×9-15 |

|

Rear wheel width(mm) |

1000 |

Rear wheel specifications(/) |

650-10 |

Operational Benefits

Enhanced Productivity

The combination of precise control and reduced operator fatigue translates directly to productivity gains. Operations typically see a 12-18% improvement in cycle times, with additional benefits in reduced product damage and improved inventory accuracy. The smooth, predictable operation allows for faster travel in congested areas without compromising safety.

Reduced Training Requirements

The intuitive control system significantly reduces the time required to train new operators. Basic operational competence can typically be achieved in under two hours, with advanced proficiency following within a single shift. This rapid onboarding is particularly valuable in operations with high personnel turnover or seasonal staffing variations.

Data-Driven Decision Making

The integrated telematics system provides unprecedented visibility into material handling operations. Managers can access detailed reports on equipment utilization, operator performance, energy consumption, and maintenance requirements. This data supports informed decisions regarding fleet sizing, operational scheduling, and preventive maintenance planning.

Implementation and Support

Customized Performance Configuration

We work closely with each client to configure the forklift's performance characteristics to match specific operational requirements. This includes programming customized performance profiles, setting appropriate speed limitations, and configuring the telematics system to provide the most relevant operational data.

Comprehensive Operator Training

Our implementation process includes thorough operator training that focuses on leveraging the advanced features to maximize both productivity and safety. This training combines classroom instruction, hands-on operation, and performance assessment to ensure operators can fully utilize the equipment's capabilities.

Ongoing Optimization Support

Our relationship continues long after implementation, with periodic performance reviews and software updates that introduce new features and enhancements. This ongoing support ensures your investment continues to deliver value as your operational requirements evolve.

Applications

This high-performance electric forklift is particularly suited for operations where precision, efficiency, and operator comfort are prioritized. Typical applications include:

High-value manufacturing and assembly operations

Food and pharmaceutical processing facilities

Electronics and precision instrument warehouses

Multi-shift distribution centers

Operations with mixed-experience operator teams

Invest in Your Team's Well-being

A comfortable operator is a productive operator. Upgrade your fleet to the Ergonomic Electric Forklift and see the difference a human-centered design makes to your safety records and bottom line.

•Request an Ergonomic Assessment: Let our specialists evaluate your current fleet and provide a detailed report on potential fatigue risks.

•Schedule an Operator Training Session: See how quickly your team adapts to the intuitive and comfortable controls.

•Inquire about Comfort Upgrade Packages: Ask about specialized heating/cooling systems and advanced seating options.

Contact our Safety & Efficiency Consultants today to learn more about the Ergonomic advantage.