High Efficient Good Quality 2Ton Diesel Forklift Cheap Price Good Powerful Hot Sale

Ideal for Warehousing & Manufacturing: Enhance Storage Density, Eliminate Emissions, and Reduce Total Operating Costs.

Description

Diesel engines have high compression ratios and thermal efficiency, and can generate significant torque and power. This enables diesel forklifts to have stronger power when transporting heavy objects, making it easy to handle various heavy cargo loading, unloading, and handling tasks. For example, in some large warehouses, diesel forklifts can stably and efficiently handle goods weighing several tons.

Diesel forklifts can maintain stable power output for a long time, suitable for continuous high-intensity operations. In some factories or logistics centers that require long-term continuous handling of goods, diesel forklifts can work continuously for several hours or even longer without significant power loss, thereby improving operational efficiency.

Core Advantages

As essential handling equipment in modern logistics and industry, our forklifts excel in efficiency, flexibility, safety, and economy, making them a powerful tool for reducing costs and increasing productivity.

1. High Efficiency, Faster Turnover

Mechanized rapid loading, unloading, transporting, and stacking significantly shorten operational cycles.

A single forklift can replace 8–15 manual laborers, substantially saving labor resources while improving operational accuracy.

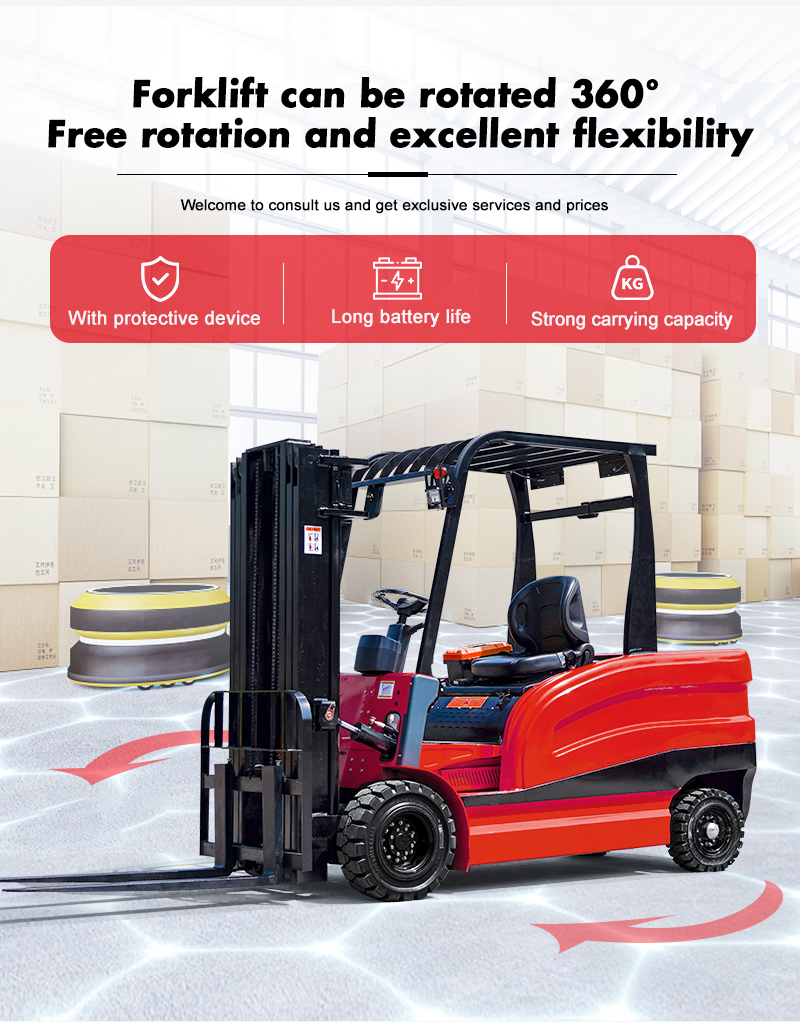

2. Flexible Adaptation, Space-Saving

Compact design and excellent maneuverability allow easy navigation through narrow aisles and complex environments like racking spaces.

Multiple models available, including counterbalance, reach, and pallet stackers, to meet diverse needs such as horizontal transport, high-level picking, and pallet handling.

3. Safe & Reliable, Cargo Protection

Precise control enables smooth fork entry under pallets, preventing cargo collisions or falls during handling.

Standard safety features include an operator safety guard and reverse alarm to protect both personnel and equipment.

Reliable braking and steering systems further reduce accident risks.

4. Cost-Effective, High ROI

Lower initial investment and maintenance costs compared to large lifting equipment.

Effectively reduces comprehensive operating costs by minimizing labor dependency and cargo damage, delivering a high return on investment.

5. Functional Expansion, Versatile Performance

Quick attachment changeover (e.g., boom, side shifter, clamp) to handle goods of various shapes and sizes with ease.

Compatible with various pallets and containers for unitized handling, maximizing operational efficiency.

Specifications

|

Wheelbase(mm) |

1930 |

Minimum turning radius(mm) |

2670 |

|

Front overhang(mm) |

300 |

Load center distance(mm) |

500 |

|

Front wheel width(mm) |

1010 |

Front wheel specifications(/) |

28×9-15 |

|

Rear wheel width(mm) |

1000 |

Rear wheel specifications(/) |

650-10 |

Our Services

We understand that different working scenarios require tailored solutions. Therefore, we provide a one-stop "Scenario-based + Personalized" service.

Professional Model Selection: Based on your specific application (e.g., logistics warehousing, production workshops), budget, and operational needs (e.g., high-efficiency handling, low energy consumption), we recommend the most suitable forklift model.

Hands-On Experience: We offer on-site test drives or video demonstrations so you can experience the equipment's handling, lifting efficiency, and cabin comfort firsthand.

Custom Modifications: For special working conditions (e.g., cold storage, explosion-proof requirements), we provide customized modifications to the power system, hydraulic components, and body structure to ensure stable performance in extreme environments.

Typical Application Scenarios

Our mini electric forklift is an efficiency expert in the following scenarios:

Logistics & Warehousing Centers

Pallet handling (storage, put-away, picking, dispatch) in narrow aisles with high-density racking.

Compact design for excellent maneuverability; zero emissions ensure clean indoor air, significantly improving storage density and turnover efficiency.

Manufacturing Workshops

Transporting raw materials from storage to production lines and moving finished goods to temporary storage areas. Smooth and quiet operation minimizes disruption to the production environment; efficiently replaces manual labor, ensuring production rhythm.

Food & Pharmaceutical Industries

Handling food, pharmaceuticals, and raw materials inside temperature-controlled cold storage or clean rooms.

Pollution-free and zero emissions, fully complying with strict hygiene and environmental standards. Cold storage modification available for reliable performance in low-temperature environments.

Retail & E-commerce Fulfillment

Restocking shelves, order picking, and loading preparation in back-end warehouses of supermarkets or e-commerce distribution centers.

The agile body is ideal for working in congested areas, responding quickly to frequent goods movement needs.

Public Venues (Airports, Libraries)

Handling luggage, books, equipment, or supplies.Quiet and clean operation does not disturb the public, making it the ideal choice for environments where quality is paramount.

Frequently Asked Questions (FAQ)

Q1: What is the biggest advantage of your electric forklift compared to diesel/LPG models?

A1: The core advantages are indoor environmental friendliness (zero emissions, low noise) and lower total operating costs. Electric forklifts don't require fuel—electricity costs are significantly lower than fuel costs—and maintenance is simpler, with no need for engine, spark plug, or exhaust system upkeep.

Q2: How long does it take to charge the battery? Can it last a full shift?

A2: A standard full charge takes approximately 8-10 hours. We highly recommend opportunity charging—topping up the battery during breaks or lunch—which easily supports a full 8-hour shift. Additionally, we offer an optional fast-charger that can significantly reduce charging time.

Q3: Is this forklift suitable for cold storage applications?

A3: Yes, it is. We offer a professional cold storage modification kit (including specialized hydraulic oil, seals, and electrical system protection) to ensure stable performance in harsh environments as low as -30°C, making it ideal for the food cold chain industry.

Q4: Can I fit the forklift with different attachments?

A4: Absolutely. Our forklifts come standard with a side-shifter and can be easily adapted for various common attachments such as roll clamps, push-pulls, and rotators. Please inform us of your specific needs, and we will recommend the most suitable attachment solution.

Q5: What after-sales service and support do you provide?

A5: We provide comprehensive after-sales support, including:

Operation & Maintenance Training: Ensures your team can use the equipment correctly.

Rapid Spare Parts Supply: We maintain a local parts inventory to minimize downtime.

Professional Technical Support: We offer phone, online, and on-site technical service for quick response and issue resolution.

Contact us now for a free consultation and on-site demonstration!

Leave your inquiry today and let our experts help you find the perfect forklift solution tailored to your needs.